Markets Served

Delivering precision-engineered solutions across automotive, appliances, medical, and consumer industries with specialized expertise and quality standards

Automotive Excellence

As a trusted Tier 1 Supplier, we manufacture complex automotive components including instrument panel assemblies, interior and exterior trim including paint capabilities for major OEMs across North America.

Instrument Panel Assemblies

Complex multi-component instrument panel systems with integrated electronics housing and premium finish quality.

Interior Components

Center consoles, door panels, and trim pieces with advanced materials and Class-A surface finishes.

Quality Certified

ISO/TS 16949 certified facilities ensuring automotive quality standards and supply chain reliability.

Appliance Manufacturing

Providing durable, high-quality molded components for home appliances with focus on heat resistance, UV stability, and long-term performance for major appliance manufacturers.

Control Panels

Durable control panels for home appliances with heat resistance and UV stability for long-lasting performance.

Appliance Housing

Structural components and housings for major appliances with textured finishes and impact resistance.

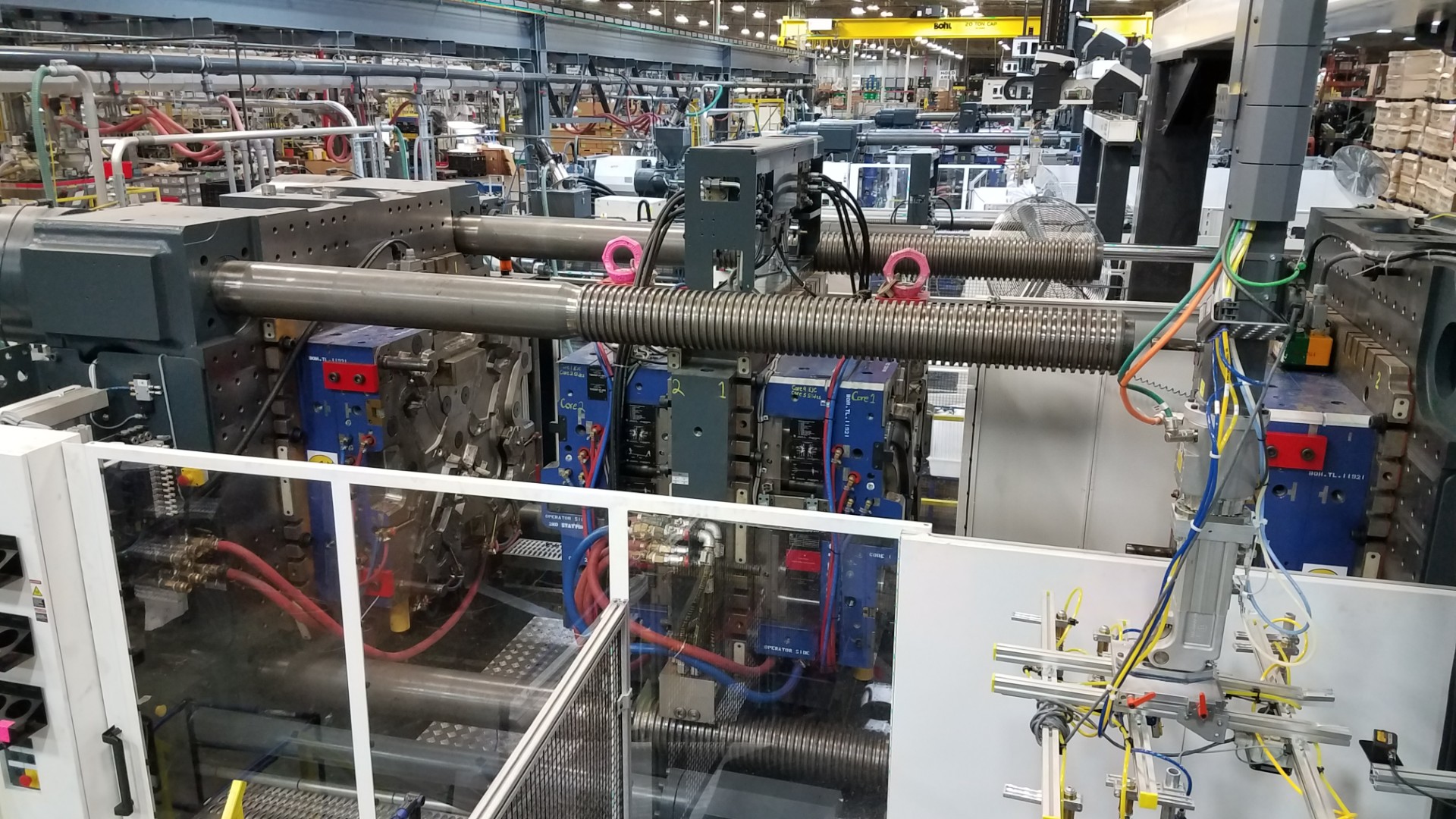

High Volume Production

Efficient manufacturing processes for high-volume appliance component production with consistent quality.

Medical Device Manufacturing

FDA-compliant cleanroom manufacturing for medical device components, surgical instruments, and diagnostic equipment housing.

Device Housing

Precision housings for diagnostic equipment and medical devices with sterilizable materials.

Surgical Components

High-precision components for surgical instruments with stringent quality and safety requirements.

FDA Compliant

ISO 13485 certified facilities with cleanroom manufacturing and full regulatory compliance.

Consumer Products

High-volume manufacturing of consumer product components including appliance parts, electronic housings, and protective cases with focus on durability and aesthetics.

Electronics Housing

Lightweight, durable housings for portable electronics with impact resistance and premium finishes.

Appliance Components

Control panels, housings, and structural components for home appliances with UV stability and heat resistance.

Sustainable Materials

Environmentally conscious manufacturing with recycled materials and sustainable production practices.

, MI/HAAS-Exterioir-1.jpg)

, MI/HAAS-Exterioir-2.jpg)

, MI/HAAS-Interior-1.jpg)

, MI/Range-Exterior-1.jpg)

, MI/Range-Interior-1.jpg)

, MI/Range-Interior-2.jpg)